It has been a while since the last “Getting to Know” feature on OtW, and I’m very pleased to feature in this instalment a woodworker who has not only taken a long hard look at how to preserve the woodcrafts, but then acted to foster engagement and enthusiasm amongst the next generation of woodworkers. Community is topic that is constantly revisted as part of the “Getting to Know” series, and I am constantly fascinated by the different ways in which we as woodworkers experience our international community, and how we find ways to contribute to, and express, that community. Kerryn Carter, the subject of this month’s feature, has certainly given a great deal to the community, and is a great example of how we can all make the woodcrafts accessible and relevant to the next generation of craftspeople.

So, without further ado, let’s get to know Kerryn Carter.

Kerryn Carter of The Tool School

1. So many people complain about the decline of ‘shop class, and the lack of woodwork education in schools, but very few do anything about it. Where did the idea for Toolschool come from? And how did you go about setting it up?

The decline of shop class is an interesting one. I see a total contradiction between the beautiful work exhibited at wood shows of high school students and the disappointing first hand accounts of what shop class actually entails for most students. I have come to conclude that these exhibited student works are the happenstance of 2 factors: a school has access to tools, machines and materials despite the funding and insurance issues that plague most schools and the students have access to an incredible teacher(s). The skills that woodshop students gain these days seems to me can vary widely depending on those factors.

Once you acknowledge that shop decline is a “thing” and combine it with the digital age where kids are living their lives on screens you see that woodshop faces some serious challenges. I think those challenges are not insurmountable.

How? The age of handmade and learning practical skills (part of the Maker Culture) has returned. The appreciation of something that someone has made without the assistance of a factory in China is coming back into mainstream culture and I often use Instagram and Youtube and Cable television as evidence. There is sustained interest in how furniture and things are made because the doors to peoples workshops which were once closed are now open and the audience is invited right up to the machine or the tool that makes the thing.

The age of handmade I think has also been given a massive super boost by the DIY culture. And yes i think we owe a debt to those reality shows that put DIY on the map.

As a result, awareness of the Maker Culture is on the rise and some of those who are noticing are parents. Those parents are keen to start teaching their children practical skills as early as possible but most are unable to because they don’t have the skills themselves. So suddenly the child of a handy parent has an advantage. That is really where I come in. The kids of parents who are not handy are sent to my “school”.

What I really do is this….I teach children up to high school age. I hope to give them some real skills, love and determination to take whatever card they are dealt at their high school (in terms of tools, machines, materials and teachers) and make the most of it. Do I want them all to become woodworkers? Not necessarily. I count my success in seeing a child become and adult who is unafraid of picking up a tool and using it to help themselves.

Where did the idea for Toolschool come from? Toolschool came from having my kids in my own woodwork shop (like almost every other kids woodwork teacher!!). I found that (as most woodworkers find) that they pick up skills quickly and with a bit of guidance can go a long way to making something. Stuart Faulkner who was my woodwork teacher for 4 years saw what I was doing with my own children and suggested that I teach other peoples children.

How did I go about setting up Toolschool? I read every childrens woodwork book on the market. I picked up a lot of tips but they still left me a bit cold in terms of the actual projects they were making. I realised that I had to compete with Minecraft and Angry Birds and quite simply a cooking utensil stand and a herb container was not going to cut it. So I spent (and still spend) a large amount of time coming up with the project ideas themselves to compete with my digital rivals. I also use a lot of 2 handed tools because 2 hands on tool = no hands near blade.

Steam-punk wooden watches made by Toolschool students

2. Making things by hand can be so satisfying, it is afterall one of the reasons we work wood. How do the kids respond as they pick up new skills or complete a project? And what sort of projects do you cover to enthuse them?

I make my classes fun but you can get that at soccer or art classes….at the end of the day its hard to compete with going home with an item you have made yourself to use in everyday life like a bag tag or magic wand or fighter jet or boat that really floats or a fishing rod or raft you have learnt to lash. Fun is a factor but its really in the area of self fulfilment that kids really respond to. It goes like this…I teach them how certain tools are used, they use those skills to make something, they decide exactly how they want the project to look, the completed project is self fulfilling and reinforces the value of the skills just used. Just to reiterate the actual projects themselves are key to my school success. Boring projects mean bored kids no matter that the skills taught are cool.

Who doesn’t want to make Han Solo style wooden blaster?

3. As well as teaching woodwork you’re a dab hand at upcycling (the retro garage bedroom was amazing!), and a talented carver – the mini acanthus leaves on the mallet build, and the carving on your Fenderette, were wonderful, so you’re clearly drawing from a wide skill base. What is your woodworking background – how and when did you start woodwork?

I grew up in my Dads woodwork shop seeing an endless procession of furniture walking out the door. I always dreamed of being a woodworker myself. He told me I had to be a “white collar” professional before he would teach me woodwork (he was a boilermaker by trade and wanted to see me “do better than him” if you like). So for the large part of a decade I was an accountant and then a lawyer. My father died suddenly while I was still a lawyer. I began learning woodwork with Stuart Faulkner 2 weeks after my fathers death. Stuart had just finished a stint as the head of fine woodwork at the Sturt School of Wood in Mittagong (just outside of Sydney) and was looking for private students. I have not worked as a lawyer since my fathers death but am still considered to be a practising lawyer. I transplanted my fathers workshop into my garage and conservatory and have built on it over the years. I stayed with Stuart for 4 years. I am now on my own and rely on woodworking magazines such as The Wood Review and Lost Art Press and instagram for learning new skills.

In terms of upcycling I have always had an interest in upcycling discarded furniture for 2 reasons. First I have a love of paint effects and how easy it is to transform boring white poly into something that wows people. Second I must be a greenie at heart because I hate seeing even a boring white poly piece of furniture (and broken even) wasted and unloved.

In terms of carving that was probably “upcycled” too…I learnt traditional chiseling skills while with Stuart Faulkner so I took those skills and after a few Youtube tutorials I tried my hand at the Fenderette. I will say this to you Kieran, only after I saw the initial results of my carving did I decide to go public with the carving attempt!! I must be a coward!! But I didn’t want to have a mega carving fail in front of the entire woodworking community!!! lol!! The Woodworker Journal from 1901 was excellent as a source of encouragement as carving was so mainstream in those days that the author had no fear whatsoever in encouraging anyone with a gouge to attempt a large scale carving. The Fenderette was the perfect beginners carving project in reality because all mistakes (of which there were plenty) are at foot level and never see direct light due to the design of the top.

Kerryn’s hand carved Fenderette

4. Ensuring the survival of the woodcrafts is a preoccupation for many woodworkers, and one that relies on teaching skills and engaging the next generation. As someone who is at the forefront of introducing young people to woodwork, what advice would you offer woodworkers who want to share woodwork with their children, nieces and nephews?

I have 5 tips!! 1. Safety is paramount (glasses, shoes, sunscreen) 2. No fingers near moving blades…none ever! 3. Always use a vise I find a Workmate good but anything to stop kids from having to support a workpiece. 4. I don’t ever measure for square (and it follows that almost everything I make does not rely on perfectly square) 5. When I can I let the kids guide what we make…its my job to decide how to make it….. oh and an extra bonus tip 6. Always slightly overestimate to a kid how long a project might take (expectation management is still important).

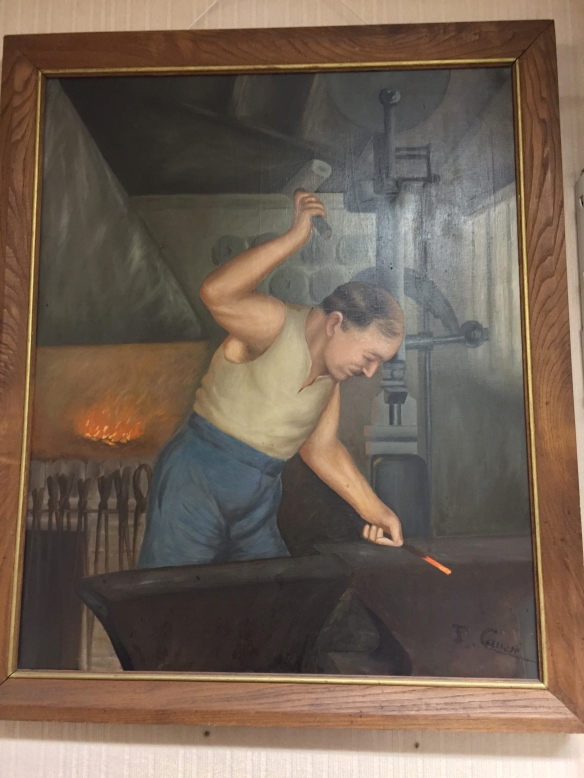

Mallett with hand carved acanthus leaf detail

5. As well as being active on Instagram you recently started adding Youtube content – what is next for Toolschool? Do you have plans for further developments?

Lots more great kids projects. There is a book coming and it will share with everyone my project designs and tool kits and methodologies for how to teach kids woodwork. Youtube is really being set up as a teaching tool where I will give kids woodwork pointers via video. So yes Youtube is certainly there and I do love the format although i seem to be extremely unpopular!!! Thats ok though because I want a permanent record of my work and I am happy to have it there.

6. Finally, when can we expect to see a Toolschool hammer juggling tutorial on YouTube

Lol whoa I have never thought of having a hammer flipping tutorial! The hammer flipping is a fine art that I learnt while standing in my workshop contemplating life. It never fails to horrify people.

Kerryn will be attending Woodworking in America on 16-18 September in Kentucky. Do say hi if you see her there.